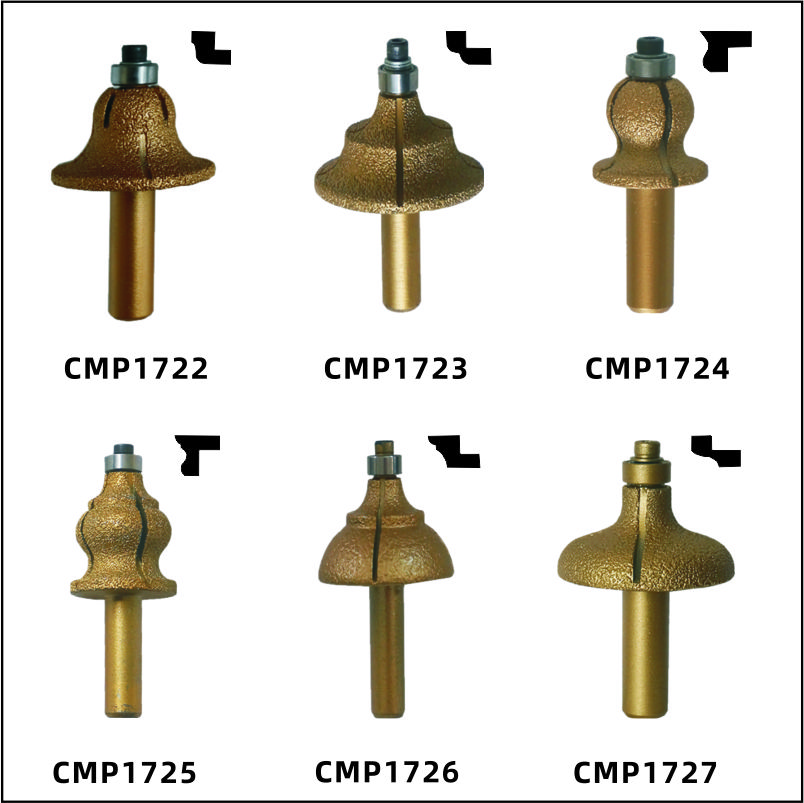

| Material | Diamond |

| Item No. | CMP1711-1716 |

| Diameter | 65mm75mm,85mm, |

| Thickness | 10mm,20mm,30mm |

| Feature | 1.Processing: Vacuum brazed,For dry and wet profiling granite, marble and limestone. Maximum RPM: 6000. |

| 2.Machine: Hand machine, CNC machine. | |

| 3.Connect: M14, 5/8”-11, ½ Gas male arbor, CNC | |

Diamond profile wheel is a specialized grinding or cutting tool used in various industries, particularly in construction, stone fabrication, and glass processing. These wheels are embedded with industrial diamonds (the hardest known material) to provide superior cutting performance on hard, abrasive materials like:

Common Applications

Stone & Tile Cutting: Granite, marble, porcelain, ceramic.

Glass & Mirror Processing: Precision cutting and shaping.

Concrete & Masonry: Grooving, trimming, and profiling edges.

Aerospace & Composites: Cutting carbon fiber and reinforced materials.

Key Features

✔ Diamond Grit: Synthetic diamonds bonded to the edge for extreme durability.

✔ Bond Types:

Metal Bond (Most Durable) – For hard materials like granite.

Resin Bond (Smoother Finish) – For glass, ceramics.

Hybrid Bonds – Balanced performance.

✔ Segmented/Continuous Rim:

Segmented – Better cooling, ideal for masonry/concrete.

Continuous Rim – Cleaner cuts, best for tile/glass.

Advantages Over Standard Wheels

Longer Lifespan – Diamonds stay sharp much longer than abrasive grains.

Higher Precision – Maintains profile accuracy over time.

Faster Cutting – Reduced heat buildup, smoother operation.

Choosing the Right Diamond Profile Wheel

Material Being Cut (Hard stone vs. soft tile).

Wet or Dry Use (Some require water cooling).

Arbor Size & RPM Compatibility (Must match your tool).

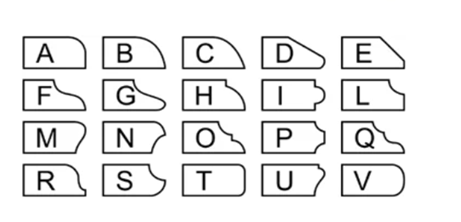

Profile Shape (V-edge, roundover, flat, etc.).