CMG1829

Diamond polishing wheel is a precision tool used to grind, hone, and polish hard materials like stone, glass, ceramics, and metals to a high-gloss finish. These wheels are embedded with diamond abrasives in various grits and bonds to achieve different levels of refinement.

Key Features & Uses

✔ High-Shine Finishing: For granite, marble, quartz, glass, and engineered stone.

✔ Progressive Grit Levels:

-

Coarse (50-200 grit) – Removing scratches, shaping.

-

Medium (200-800 grit) – Smoothing surfaces.

-

Fine (800-3,000+ grit) – Mirror-like polishing.

✔ Bond Types: -

Resin Bond – Most common, flexible for fine polishing.

-

Metal Bond – Durable, for aggressive grinding before polishing.

-

Hybrid Bond – Combines durability with smoothness.

Types of Diamond Polishing Wheels

-

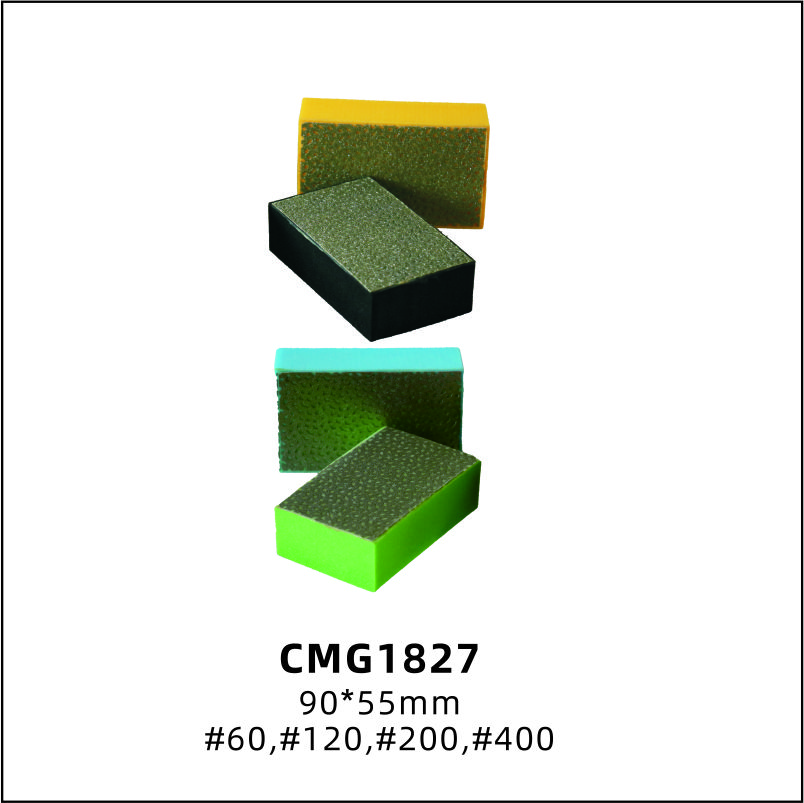

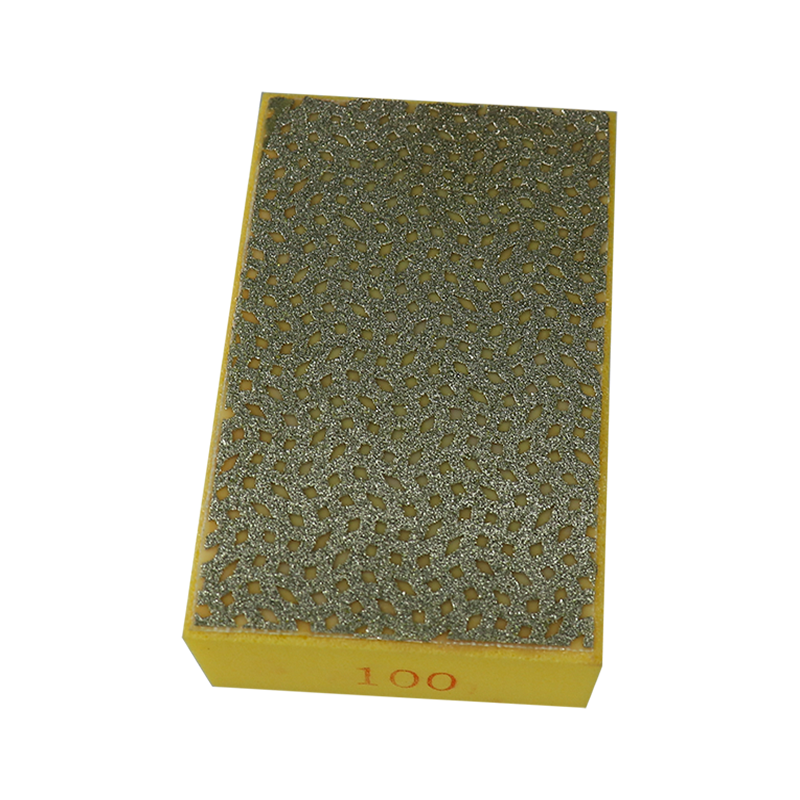

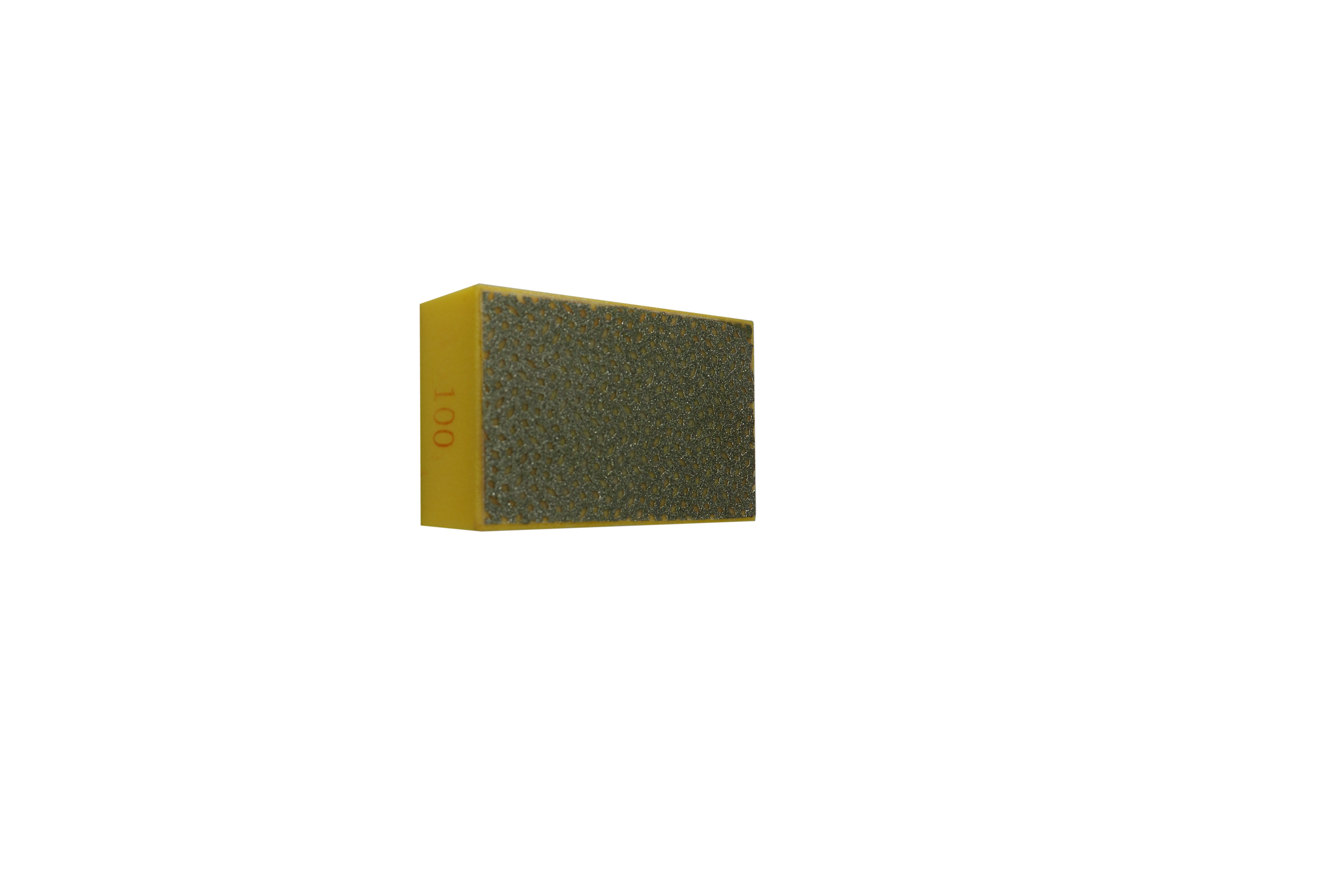

Rigid Polishing Pads – For flat surfaces (granite slabs, countertops).

-

Flexible Backing Pads – Conforms to curves (sink holes, edges).

-

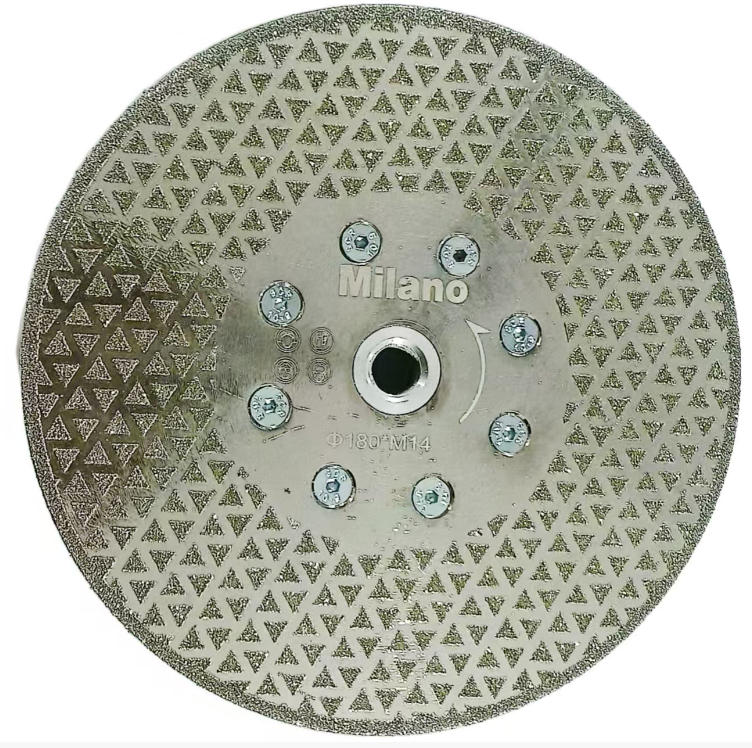

Electroplated Diamond Wheels – Thin coating for precision work (gemstones, glass).

-

Velcro-Backed Discs – Easy to replace, used with rotary tools.

Best Applications

-

Stone Fabrication: Polishing countertop edges, sink cutouts.

-

Glass & Ceramics: Beveling, lens polishing.

-

Metals & Composites: Deburring, finishing aerospace parts.

Choosing the Right Polishing Wheel

-

For Granite/Marble: Start with metal-bond (50-400 grit), finish with resin-bond (800-3,000 grit).

-

For Glass/Ceramics: Use electroplated or resin-bond fine grits (1,500+).

-

For Metals: Diamond-impregnated felt wheels for mirror finishes.

Polishing Process (Step-by-Step)

-

Grind First – Use a coarse diamond wheel (50-200 grit) to remove imperfections.

-

Hone – Progressively smoother grits (200-800) to eliminate scratches.

-

Polish – Fine grits (1,500-3,000+) with water or polishing compound for shine.

Pro Tips

-

Use Water Cooling – Prevents overheating and extends wheel life (for stone/glass).

-

Match RPM to Wheel Type – High speed for coarse grit, slower for fine polishing.

-

Clean Between Grits – Avoid cross-contamination of abrasive particles.